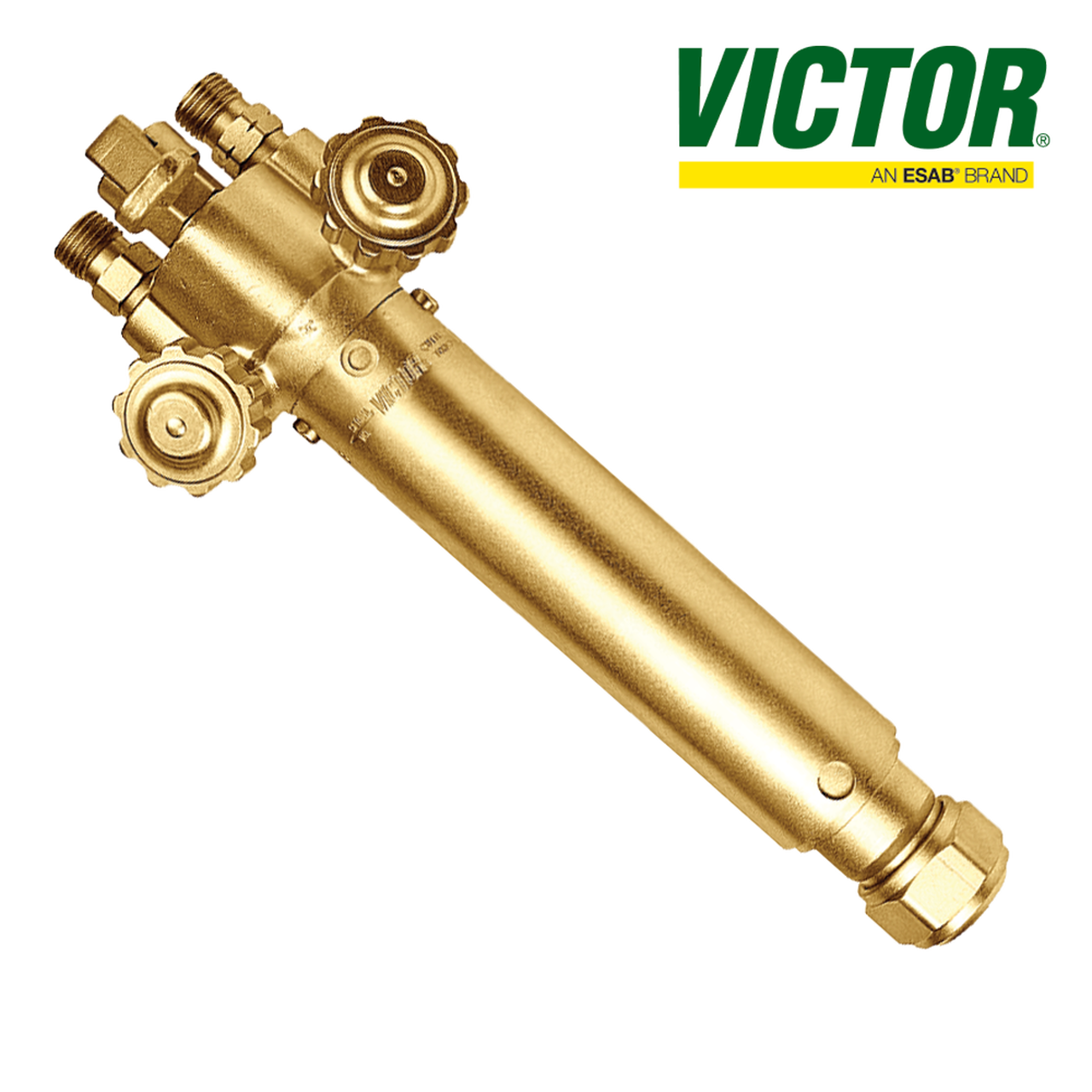

VICTOR – SHORT BARREL TORCH 8 1/2″ MT204A

- The Check Valve prevents the reverse flow of gases

- Disk assembly seals tight against seat in event of reverse flow

- Spring compresses under normal flow, moving disk assembly forward and allowing gas flow

- Accessory Reverse Flow Check Valves supplied with all machine torches or added for added operator safety

- Straight Through Design minimizes turbulence, improves cutting performance

- High Performance Mixer Design provide optimum performance

- Rugged Brass torch head and body for maximum strength

- Pre-Drilled 1.38″ (35.1 mm) Diameter Barrels for three position mounting flexibility

$694.99

Finding the Right Torch for Your Metalworking Projects – A Welder’s Perspective

As I stood in my workshop last week, preparing to tackle a complex automotive restoration project, I realized just how much my trusty Victor Short Barrel Torch has transformed my metalworking capabilities over the years. The precision, control, and versatility this tool offers has been nothing short of game-changing for my business and creative endeavors. After fielding countless questions from colleagues and apprentices about this essential piece of equipment, I decided it was time to create the comprehensive buying guide I wish I’d had when I first entered the trade.

Whether you’re a seasoned professional looking to upgrade your existing setup or a passionate hobbyist taking your first steps into serious metalworking, understanding the ins and outs of the Victor Short Barrel Torch can make all the difference in your projects. Let me walk you through everything you need to know about this exceptional tool.

What Exactly Is a Victor Short Barrel Torch?

The first time I held a Victor Short Barrel Torch, I immediately noticed how different it felt compared to standard cutting torches. The Victor Short Barrel Torch is a specialized oxy-fuel cutting and heating torch that, as the name suggests, features a shorter barrel than traditional models. Manufactured by Victor Technologies (now part of ESAB), this torch has earned its reputation as one of the most reliable and precise cutting torches on the market.

The compact design isn’t just about saving space—it fundamentally changes how you interact with your workpiece. The reduced length creates a more balanced tool that provides exceptional control for detailed cutting operations while reducing operator fatigue during extended use. This might seem like a small difference on paper, but in practice, it’s transformative, especially when working in tight spaces or on intricate projects.

I remember my first automotive restoration project using this torch—reaching into the wheel well of a 1967 Mustang to make precise cuts would have been nearly impossible with my old standard barrel torch. The short barrel design made all the difference, allowing me to maneuver with confidence in that restricted space.

What Can You Use a Victor Short Barrel Torch For?

Over my 15 years in metalworking, I’ve put my Victor Short Barrel Torch through its paces on countless projects, and its versatility continues to impress me. While primarily designed for cutting operations, this tool’s capabilities extend far beyond simple straight cuts.

Cutting Operations

The primary function of this torch is precision cutting of ferrous metals. I’ve used it to cut everything from 1/8-inch mild steel sheet for artistic sculptures to 6-inch thick structural steel during heavy industrial work. The flame control is exceptional, allowing for clean, slag-free cuts when properly adjusted.

Heating Applications

Beyond cutting, I’ve found the torch invaluable for heating operations. When I need to bend metal for custom fabrication, the focused flame provides controlled heat exactly where needed. This has been particularly useful when creating curved components for ornamental ironwork and custom furniture pieces.

Brazing and Silver Soldering

With the right tips (which I’ll discuss later), the Victor Short Barrel Torch is excellent for brazing and silver soldering operations. Last month, I used mine to repair a vintage copper kettle, and the precision flame control allowed me to apply heat exactly where needed without damaging the surrounding material.

Automotive Repair

For those working in automotive restoration like myself, this torch is indispensable. From cutting rusted panels to heating seized components for removal, the maneuverability of the short barrel design makes working on vehicles significantly easier, especially in those tight engine compartments where space is at a premium.

How Does the Victor Short Barrel Torch Differ from Standard Models?

When I upgraded from my standard Victor torch to the short barrel version, the differences became immediately apparent. Here’s what separates this specialized tool from its standard counterparts:

Length and Balance

The most obvious difference is the barrel length. While standard torches typically have barrels measuring 12-16 inches, the short barrel variant comes in at around 8 inches. This 4-8 inch difference might not sound significant, but it dramatically improves balance and reduces the leverage effect that causes hand fatigue during extended use.

I recall spending a full day cutting patterns for a large sculpture installation—by the end, my wrist and forearm would have been screaming with my old torch. With the short barrel, I finished the day with minimal fatigue.

Maneuverability

The compact design allows for unprecedented maneuverability in confined spaces. When I’m working on automotive restoration projects, navigating around frame rails and body panels becomes much more manageable with the short barrel design.

Flame Control

I’ve found that the shorter distance between the mixing chamber and the tip provides slightly better flame control, especially when making detailed cuts. The flame seems more responsive to adjustment changes, allowing for precise fine-tuning.

Weight Distribution

The weight distribution of the short barrel torch feels more natural in hand, with the center of gravity closer to your grip. This subtle difference reduces strain during those long cutting sessions that are inevitable in busy fabrication shops.

Key Features of the Victor Short Barrel Torch

After using various models of the Victor Short Barrel Torch over the years, I’ve come to appreciate several standout features that set this tool apart:

Durable Construction

Victor doesn’t cut corners on build quality. My first torch lasted over eight years of daily professional use before needing any significant maintenance. The solid brass construction provides excellent durability while efficiently conducting heat away from your hand during operation.

Ergonomic Design

The handle design features contoured grips that fit naturally in your hand. This might seem like a minor detail, but when you’re using a torch for hours on end, ergonomics make a tremendous difference in comfort and control.

Precision Valves

The needle valves for both oxygen and fuel gas control offer exceptional precision. I can make minute adjustments to achieve the perfect flame for whatever task I’m tackling, whether it’s a rough cut through thick material or delicate heating for a brazing operation.

Universal Compatibility

The torch accepts standard Victor cutting attachments and tips, making it incredibly versatile. I’ve built up quite a collection of specialized tips over the years, and they all work flawlessly with the short barrel model.

Safety Features

Safety is paramount when working with oxy-fuel equipment, and Victor has incorporated several important safety features. The torch features built-in check valves to prevent dangerous flashbacks, and the gas passages are separated to prevent mixing until they reach the tip.

Cutting Thickness Capability: What Can It Handle?

One of the most common questions I get from colleagues considering this torch is about its cutting capacity. Let me be clear: despite its compact size, the Victor Short Barrel Torch doesn’t sacrifice cutting power.

With the appropriate tips and proper gas pressure settings, this torch can effectively cut steel plate up to 12 inches thick. However, I find its sweet spot is in the 1/4 inch to 4-inch range, where it delivers exceptionally clean cuts with minimal slag.

I recall a particularly challenging job requiring precise cuts through 3-inch steel plate for a custom machinery base. The short barrel torch performed flawlessly, allowing me to follow my marked lines with accuracy that would have been difficult to achieve with a standard torch.

That said, cutting capacity depends significantly on several factors:

- The specific cutting tip used

- Proper gas pressure settings

- Preheat time for thicker materials

- Cutting speed

- Material composition

For very thick materials (over 6 inches), I recommend taking your time with preheating and maintaining a steady hand. The short barrel design actually helps here, as it reduces the fulcrum effect that can cause wavering when cutting thick plate with a standard torch.

Industries That Rely on the Victor Short Barrel Torch

Throughout my career, I’ve worked with professionals across numerous industries who swear by the Victor Short Barrel Torch. This tool has found a home in:

Metal Fabrication Shops

In general fabrication shops like the one I started in, the short barrel torch is often the go-to for precision cutting tasks. Its versatility makes it ideal for the varied work that comes through these shops daily.

Automotive Restoration and Repair

As I mentioned earlier, automotive professionals particularly appreciate the maneuverability in tight engine compartments and when working on body panels. The precision cutting allows for clean removal of rusted sections without damaging surrounding good metal.

Shipbuilding and Repair

Colleagues in the maritime industry tell me they value the torch’s durability in harsh environments and its ability to cut through various thicknesses of steel used in vessel construction and repair.

Sculpture and Artistic Metalwork

Many artistic metalworkers I’ve mentored gravitate toward the short barrel torch for its exceptional control when creating intricate cuts for sculptural pieces. The precision it offers allows artists to execute detailed designs that would be challenging with standard equipment.

Construction and Demolition

On construction sites, the torch’s portability and versatility make it valuable for both construction and demolition tasks, from cutting rebar to removing structural steel during renovation projects.

Manufacturing

In manufacturing environments, especially those producing custom metal components, the short barrel torch provides the precision needed for specialized cutting tasks that automated systems can’t handle.

Where to Purchase a Victor Short Barrel Torch

When I decided to upgrade to my first Victor Short Barrel Torch, finding a reputable source was my top priority. Over the years, I’ve purchased equipment from various sources and can recommend several reliable options:

Welding Supply Specialists

Local welding supply shops often provide the best overall experience. They typically have knowledgeable staff who can answer questions and help you select the right accessories. My current torch came from a family-owned welding supply store, and their expertise in helping me configure the perfect setup was invaluable.

Industrial Supply Companies

National industrial supply companies like Airgas and Praxair carry Victor products and often have comprehensive inventories of accessories and replacement parts. I’ve used these sources when needing specialized components not stocked by my local supplier.

Online Retailers

Online industrial supply retailers offer convenience and often competitive pricing. When purchasing online, I recommend sticking with established industrial suppliers rather than general merchandise platforms to ensure you’re getting genuine Victor products.

Used Equipment

For those on a budget, quality used equipment can be an option. I started with a second-hand Victor torch that served me well for years. When buying used, inspect for damage to valves, threads, and the mixing chamber, and always test the equipment before putting it into service.

Understanding the Price Range

A topic I’m frequently asked about is cost. The investment in quality equipment pays dividends in performance and longevity, but understanding the price range helps with budgeting your purchase.

The Victor Short Barrel Torch itself (handle only) typically ranges from $150 to $250, depending on the specific model and where you purchase it. However, to have a functional system, you’ll need additional components:

Complete Cutting Outfit

A complete cutting outfit, including the torch handle, cutting attachment, tips, hoses, regulators, and a cart or carrying case, generally ranges from $700 to $1,200. This represents a significant investment but provides everything needed to start working immediately.

Building Your Own Setup

Many professionals, myself included, prefer to build a custom setup by purchasing components individually over time. This approach allows you to select exactly the parts that meet your specific needs and can sometimes be more economical in the long run.

Additional Costs to Consider

When budgeting, don’t forget to include:

- Multiple cutting tips for different material thicknesses

- High-quality hoses that will stand up to workshop conditions

- Reliable regulators for consistent gas pressure

- Safety equipment including proper gloves and eyewear

- Tip cleaners and maintenance tools

While premium pricing might seem steep initially, I’ve found that quality torch equipment is one area where “buy once, cry once” truly applies. My Victor equipment has outlasted cheaper alternatives by years, making it more economical over time despite the higher upfront cost.

Compatible Gases: Fueling Your Torch

The Victor Short Barrel Torch is designed to work with multiple fuel gases, providing flexibility based on your specific application needs. Throughout my career, I’ve used various gas combinations, each with distinct advantages:

Acetylene

Acetylene remains the most common fuel gas for cutting operations, and for good reason. It produces the hottest flame temperature (around 6,000°F when combined with oxygen) and allows for the fastest cutting speeds. I use acetylene for the majority of my cutting work, especially when speed is important.

Propane

For heating operations and some cutting applications, propane offers advantages including lower cost, safer storage, and greater availability. The flame temperature is lower than acetylene (around 5,000°F with oxygen), but I find it works well for heating operations and cutting thinner materials.

Natural Gas

Some shop setups utilize natural gas lines. While not as hot as acetylene, natural gas is economical for shops with high volume heating needs. I’ve used natural gas primarily for heating operations rather than precision cutting.

MAPP Gas

MAPP gas (actually MAP-Pro these days) is a propylene-based alternative that burns hotter than propane but not as hot as acetylene. I’ve found it to be a good middle-ground option when acetylene isn’t available or practical.

Alternative Fuel Gases

Other gases like propylene and other fuel gas mixtures are compatible with the Victor torch when used with the appropriate tips. These specialized gases sometimes offer advantages for specific applications.

Regardless of which fuel gas you choose, the Victor Short Barrel Torch performs admirably. I recommend acetylene for professional cutting applications where performance is paramount, but don’t hesitate to use alternatives when they better suit your specific needs or working environment.

Welding vs. Cutting: Can It Do Both?

A common misconception I encounter is that the Victor Short Barrel Torch is exclusively for cutting. In reality, this versatile tool can handle both cutting and welding operations with the right attachments.

Cutting Operations

With a cutting attachment and appropriate cutting tips, the torch excels at precision cutting of ferrous metals. The oxygen lever on the cutting attachment provides a controlled blast of oxygen that creates the cutting reaction in preheated metal.

Welding Capabilities

By replacing the cutting attachment with welding tips, the same torch handle transforms into an effective oxy-fuel welding tool. I regularly use mine for welding thinner materials (up to about 3/16″) and for brazing operations.

Heating Applications

Beyond cutting and welding, specialized heating tips allow for controlled heating of materials for bending, straightening, or heat treatment. I find this particularly useful when working on automotive restoration projects that require controlled heat application.

The multi-function capability of the Victor torch is one of its greatest strengths. Rather than purchasing separate tools for different operations, this single handle can serve multiple purposes with the appropriate attachments—a significant advantage for both professionals and hobbyists with limited budgets or storage space.

Setting Up Your Victor Short Barrel Torch: A Step-by-Step Guide

Proper setup is crucial for both safety and performance. Here’s my step-by-step process for setting up a Victor Short Barrel Torch system:

1. Equipment Assembly

Start by connecting the regulators to their respective cylinders, ensuring the connections are tight but not over-tightened. Attach the hoses to the regulators using the appropriate fittings (green for oxygen, red for fuel gas). Connect the other end of the hoses to the torch handle, again respecting the color coding.

2. Attaching the Cutting Assembly

Connect your cutting attachment to the torch handle, ensuring the connection is secure. Select the appropriate cutting tip for your material thickness and screw it into the cutting attachment. I always check that the tip is clean and the orifices are clear before installation.

3. Pressure Setting

With the torch valves closed, slowly open the cylinder valves fully (oxygen) or partially (acetylene). Set your working pressures according to the recommendations for your specific tip size. For a #1 cutting tip with acetylene, I typically set oxygen at about 25-30 PSI and acetylene at 5-7 PSI.

4. Leak Testing

Before lighting, I always check for leaks by applying a solution of soapy water to all connections and watching for bubbles. Any leaks must be addressed before proceeding.

5. Lighting and Adjustment

I open the fuel gas valve on the torch about 1/4 turn and ignite with a spark lighter (never a match or cigarette lighter). Then I adjust for a neutral flame by slowly opening the oxygen valve. For cutting, I further adjust to achieve a clean, blue inner cone before using the cutting oxygen lever.

6. Testing

Before beginning work on your project, always test your setup on scrap material of similar thickness to ensure proper flame adjustment and cutting performance.

Essential Safety Precautions When Using a Victor Short Barrel Torch

Safety is non-negotiable when working with oxy-fuel equipment. Throughout my career, I’ve maintained a strict safety protocol that has kept me injury-free despite daily use of cutting torches:

Personal Protective Equipment

Always wear appropriate welding goggles with the correct shade for oxy-fuel work. Heavy leather gloves that extend past your wrist provide essential hand protection. Fire-resistant clothing and leather footwear complete the basic PPE requirements.

Workspace Preparation

Ensure your work area is free of flammable materials. I always keep a fire extinguisher rated for all types of fires within arm’s reach. When possible, work on a metal surface or use a welding blanket to protect surrounding areas from sparks and hot metal.

Cylinder Safety

Secure gas cylinders in an upright position using chains or appropriate cylinder stands. Keep cylinders away from heat sources and electrical circuits. Never use damaged cylinders or those with questionable valve integrity.

Equipment Inspection

Before each use, I inspect all equipment for damage, particularly checking hoses for cracks, cuts, or signs of deterioration. Verify that all connections are tight and that flashback arrestors are installed and functioning properly.

Proper Ventilation

Always work in a well-ventilated area. Cutting operations produce fumes that can be hazardous, especially when working with coated or galvanized materials.

Never Use Oil or Grease

Keep all equipment free from oil and grease, which can react explosively with oxygen under pressure. This includes your hands when handling oxygen fittings.

Proper Shutdown Procedure

Develop and follow a consistent shutdown procedure. I always close the torch valves first, then the cylinder valves, and finally bleed the lines by reopening and reclosing the torch valves.

Fire Watch

When working in areas with fire potential, arrange for a fire watch—someone whose sole responsibility is monitoring for and addressing any fires that might start from sparks or hot metal.

These safety practices have become second nature to me over the years, and I strongly encourage developing the same safety-first mindset. No project is worth risking your health or safety.

Compatible Tips for the Victor Short Barrel Torch

The versatility of the Victor torch comes largely from its compatibility with a wide range of tips designed for specific applications. Over the years, I’ve built quite a collection to handle various projects:

Cutting Tips

Victor’s Series 1 cutting tips are the standard for most cutting operations. They come in sizes #000 (for thin sheet metal) through #6 (for thick plate). I find myself using #0, #1, and #2 tips for most of my work, keeping the larger sizes for occasional heavy cutting.

Heating Tips

For heating operations, Victor offers various heating tip designs. The multiple-orifice tips provide even heat distribution for bending operations, while single-orifice tips concentrate heat for more focused applications.

Welding Tips

Victor welding tips come in various sizes for different material thicknesses. For general purpose welding, I rely on their Series W tips, selecting the size based on the metal thickness I’m working with.

Specialty Tips

For specific applications, Victor offers specialty tips like gouging tips for removing material without cutting through entirely, and rivet-busting tips designed specifically for removing rivets in restoration work.

Mixing and Matching

One advantage of the Victor system is standardization—tips designed for Victor equipment follow consistent threading patterns, allowing you to use tips from various series with your short barrel torch handle.

I recommend starting with a basic set of cutting tips (#0, #1, #2) and adding specialized tips as your specific project needs dictate. This approach has served me well, allowing my toolkit to evolve alongside my skill set and project requirements.

Warranty Coverage for Victor Short Barrel Torches

Understanding warranty coverage is essential when investing in professional equipment. Victor stands behind their products with solid warranty protection:

Standard Warranty

Victor typically provides a one-year warranty against defects in materials and workmanship for their torches. This covers the torch handle, valves, and basic components under normal use conditions.

Extended Coverage

Some distributors offer extended warranty options that can provide additional peace of mind, particularly for professional users who depend on their equipment daily.

What’s Usually Covered

The warranty typically covers manufacturing defects that affect functionality. This includes issues with valves, threading, and the body of the torch handle itself.

What’s Usually Not Covered

Wear items like O-rings, consumables such as tips, and damage from improper use or maintenance are generally excluded from warranty coverage. Additionally, modifications to the equipment usually void warranty protection.

Making a Warranty Claim

If you experience issues with your torch, contact your authorized Victor dealer with proof of purchase. They can help determine if your issue is covered and facilitate repair or replacement.

I’ve only had to make one warranty claim in my career, when a valve seat developed a leak shortly after purchase. The process was straightforward, and the dealer replaced the handle without question. This positive experience reinforced my confidence in both the product and the company behind it.

Precision Cutting Capabilities

For many professionals, myself included, the precision cutting capability of the Victor Short Barrel Torch is its most valuable attribute. The torch excels in applications requiring detailed cuts and careful control:

Advantages for Precision Work

The short barrel design provides better balance and reduces the fulcrum effect that can cause wavering during detailed cutting operations. I find this particularly noticeable when following complex patterns or making intricate cuts.

Template Cutting

When working with templates, the improved visibility and control of the short barrel torch allows for more accurate tracking. I recently completed a project requiring dozens of identical parts cut from 1/4″ plate, and the template-following accuracy of this torch was instrumental in maintaining consistency across all pieces.

Bevel Cutting

For preparing edges for welding, the torch allows precise control of angle and depth. This is critical when preparing joints for structural welding where bevel angles must meet specific requirements.

Small Part Fabrication

When cutting small components, the extra control provided by the short barrel design becomes even more valuable. I’ve fabricated intricate parts for custom machinery that would have been significantly more challenging with a standard torch.

High-Stakes Precision

On projects where mistakes are costly—such as when working with expensive alloys or critical components—the added precision of the short barrel torch provides valuable insurance against cutting errors.

While automated cutting systems have their place for production work, nothing beats the flexibility and adaptability of a skilled operator with a quality manual torch for custom fabrication and repair work.

Maintenance and Cleaning Best Practices

Proper maintenance extends the life of your equipment and ensures safe, reliable operation. Here’s my maintenance routine that has kept my torches performing like new for years:

Daily Maintenance

After each use, I wipe down the exterior of the torch with a clean cloth to remove soot and debris. I check all connections for tightness and inspect hoses for any signs of wear or damage.

Tip Cleaning

Clean tips are essential for proper flame characteristics. I use dedicated tip cleaners—never drills or wires that could enlarge the orifices. For stubborn deposits, soaking tips in acetone can help dissolve built-up carbon.

O-Ring Inspection

Periodically check O-rings for wear or damage, replacing them at the first sign of deterioration. This prevents leaks that can compromise safety and performance.

Valve Maintenance

If valves become stiff or sticky, a drop of appropriate valve lubricant (never oil or grease) can restore smooth operation. If valves continue to stick, professional service may be required.

Leak Testing

I perform regular leak tests by applying soapy water to connections while the system is under pressure. Any bubbles indicate leaks that must be addressed immediately.

Professional Servicing

Even with diligent maintenance, I recommend having your torch professionally serviced annually if you use it frequently. This typically includes internal cleaning, replacement of wear items, and thorough safety testing.

Storage Practices

Proper storage prolongs equipment life. I store my torch in a dedicated case, protecting it from dust and impact damage. For extended storage, I ensure the system is completely depressurized and free from moisture.

This maintenance routine might seem intensive, but I’ve found that a few minutes of care after each use prevents more significant issues and extends the useful life of the equipment substantially.

Replacement Parts Availability

One of the advantages of choosing Victor equipment is the excellent availability of replacement parts. This has been crucial for keeping my equipment operational throughout my career:

Common Replacement Parts

The most frequently replaced components include O-rings, valve stems, and various seals. These wearing parts eventually need replacement even with careful maintenance.

Finding Genuine Parts

I strongly recommend using only genuine Victor replacement parts, which are widely available through authorized distributors. While aftermarket parts might seem economical, I’ve found they often don’t provide the same fit or durability.

DIY vs. Professional Repair

Simple maintenance like O-ring replacement can be handled by most users. For more complex repairs involving internal components, I recommend professional service to ensure proper assembly and testing.

Rebuilding Services

Many welding supply shops offer torch rebuilding services, where they completely disassemble, clean, and rebuild torches with new components. This can be a cost-effective alternative to replacement when the torch body remains in good condition.

Upgrade Opportunities

When parts need replacement, it’s sometimes an opportunity to upgrade components. For example, when replacing regulators, you might choose to upgrade to models with additional features or improved performance.

The availability of parts has allowed me to maintain the same torch handle for many years, replacing only what wears out. This sustainability aspect of quality equipment is often overlooked but represents significant value over time.

Victor Short Barrel Torch vs. Competitors

Throughout my career, I’ve had opportunities to use various brands and models of cutting torches. Here’s how the Victor Short Barrel Torch compares to other options on the market:

Victor vs. Smith

Smith Equipment (now also part of ESAB alongside Victor) produces excellent torches with similar capabilities. In my experience, both brands offer comparable quality and performance, with the choice often coming down to personal preference regarding ergonomics. I find Victor handles slightly more comfortable for my hand size.

Compared to Harris

Harris torches are another quality option. They tend to be slightly lighter than Victor models, which some users prefer. However, I’ve found Victor equipment generally offers more robust construction that stands up better to workshop abuse.

Budget Alternatives

Various import brands offer significantly lower prices, but in my experience, the performance and durability simply don’t compare. I’ve seen apprentices struggle with inconsistent flame characteristics and premature failure of these less expensive options.

Heavy-Duty Alternatives

For extremely demanding applications, Victor offers heavy-duty models that provide enhanced durability. While these come at a premium price, operations with continuous heavy usage may find the investment worthwhile.

Modern Alternatives

Newer plasma cutting technology offers advantages for some applications, particularly when cutting thinner materials or non-ferrous metals. However, I still find oxy-fuel superior for thicker materials and situations requiring heating capabilities.

After trying various options throughout my career, I’ve consistently returned to Victor equipment for its balance of performance, durability, and value. The initial investment might be higher than budget alternatives, but the long-term economics strongly favor quality equipment.

User Experiences and Testimonials

Throughout my career, I’ve connected with many fellow professionals about their experiences with the Victor Short Barrel Torch. Here are some insights from the community:

Professional Fabricator Experiences

A colleague who runs a custom fabrication shop shared that their team switched entirely to short barrel torches after noticing the improved precision on detailed architectural metalwork. They reported a reduction in rework and improved consistency across their team.

Automotive Restoration Specialist

A restoration specialist I frequently collaborate with swears by the short barrel torch for automotive work. He particularly notes its advantage when working in tight engine compartments and wheel wells where standard torches are simply too unwieldy.

Industrial Maintenance Perspective

Maintenance technicians at a local manufacturing facility reported that the short barrel torch has become their go-to for in-place repairs where space constraints make standard torches difficult to use effectively.

My Personal Experience

In my own practice, the short barrel torch has been instrumental in expanding the range of projects I can confidently take on. The precision it offers has enabled me to move into more detailed artistic metalwork alongside my industrial fabrication business.

Learning Curve Considerations

New users should note there is a slight learning curve when transitioning from standard torches. Several colleagues mentioned initially feeling the torch was “too responsive” before adapting to its more precise handling characteristics.

The consensus among professionals I respect is that the short barrel design represents a meaningful improvement for precision work, though some still prefer standard torches for rough cutting of very thick materials where the additional length provides leverage.

Recommended Accessories for Your Victor Short Barrel Torch

To maximize the capability of your Victor Short Barrel Torch, I recommend several accessories that have proven invaluable in my professional work:

Quality Regulators

Invest in high-quality, two-stage regulators for both oxygen and fuel gas. These provide more consistent pressure than single-stage alternatives, resulting in more stable flame characteristics. I’ve used Victor’s professional regulator series for years with excellent results.

Heavy-Duty Hoses

Premium grade welding hoses offer better durability and flexibility in workshop conditions. I recommend twin hoses (oxygen and fuel gas bound together) in a 25-foot length for most applications, providing sufficient reach without excessive bulk.

Flashback Arrestors

While modern Victor torches include internal check valves, additional flashback arrestors at the regulator provide an extra layer of safety. This redundant protection is well worth the modest investment.

Tip Cleaners

A proper set of tip cleaners is essential for maintaining optimal performance. These precisely sized tools allow cleaning of tip orifices without enlarging them, ensuring proper flame characteristics.

Spark Lighter

A dedicated spark lighter provides safe ignition without the risks associated with matches or conventional lighters. Look for one with replaceable flints for longevity.

Cutting Guides

For straight cuts, a good cutting guide improves accuracy and consistency. I use magnetic guides for flat work and specialized pipe-cutting guides for tubular materials.

Torch Cart or Caddy

A dedicated cart for your oxy-fuel equipment improves mobility and safety. Look for models with cylinder securing chains, tool storage, and stable bases.

Safety Equipment

Beyond basic PPE, consider a dedicated welding jacket for spark protection and specialized welding goggles with appropriate shading for oxy-fuel work.

Tip Organizer

A purpose-built case for organizing and protecting your collection of cutting, heating, and welding tips prevents damage and makes selection easier when switching between applications.

These accessories represent investments in both capability and safety. While you might not need everything immediately, building your toolkit over time with quality accessories will enhance your cutting and welding operations.

Final Thoughts: Is the Victor Short Barrel Torch Right for You?

After decades in the trade and years of daily use with the Victor Short Barrel Torch, I can confidently say it represents one of the best investments I’ve made in my professional equipment. However, determining if it’s right for your specific needs requires careful consideration.

Ideal For:

- Professionals requiring precise cutting in varied applications

- Automotive restoration specialists working in confined spaces

- Fabricators creating detailed metalwork components

- Anyone prioritizing control and reduced operator fatigue

- Workshops handling diverse cutting, heating, and welding tasks

Perhaps Less Ideal For:

- Those exclusively cutting very thick materials where standard torches provide helpful leverage

- Extremely budget-constrained hobbyists just getting started

- Shops that have fully transitioned to plasma cutting for all operations

The Victor Short Barrel Torch represents the perfect balance of precision, versatility, and durability for serious metalworkers who value quality tools that enhance their capabilities. While the initial investment might exceed budget alternatives, the performance advantages and longevity make it economical over its useful life.

My recommendation is straightforward: if metalworking is more than an occasional hobby—if you value precision and comfort during extended use—the Victor Short Barrel Torch is worth every penny. It’s the rare tool that actually expands what you can accomplish rather than merely enabling it.

As with any significant tool purchase, I suggest handling the torch if possible before buying. The ergonomics and balance that make this torch special are best appreciated firsthand. Visit a welding supply store, talk with experienced users, and make an informed decision based on your specific working style and project needs.

Whatever cutting torch you ultimately choose, remember that quality tools enhance both the process and results of your metalworking journey. Choose wisely, work safely, and enjoy the satisfaction that comes from precision metal fabrication.